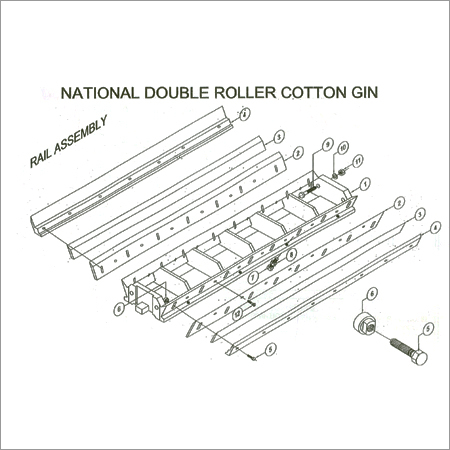

Cotton Ginning Machine Spare Parts

Product Details:

Product Description

Cotton Ginning Machine Spare Parts

We are best renowned exporter,manufacturer & supplier of Cotton Ginning Machine Parts at market leading prices from Ahmedabad,Gujarat,India

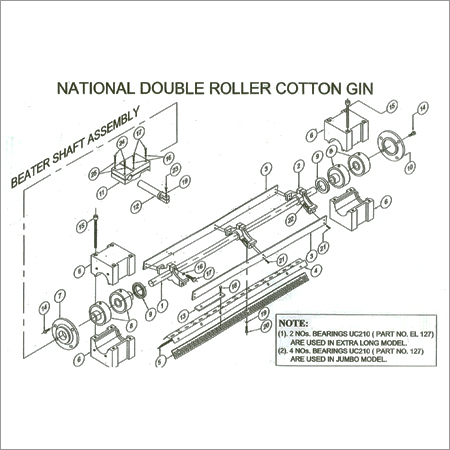

- Loosen clamping strip nut, before adjusting the beater height. Tighten fully after putting few packing plates to align the beater bearing housing.

- Beater height will be adjusted by increasing or by decreasing the no. of packing plates.

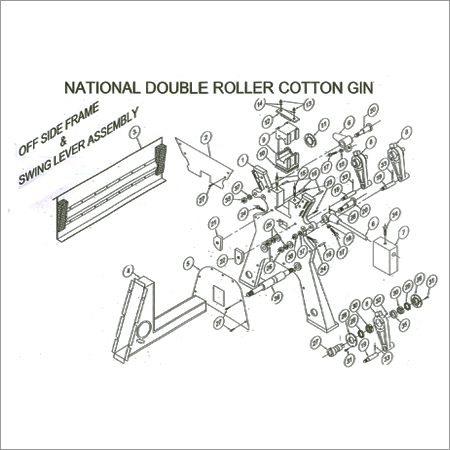

- Loosen or tighten these bolts for setting the main rail. After setting, both the bolts should

- be fully tightened.

- Loosen these nuts, before adjusting the main rail. Tighten fully after adjustment.

- Side projection of main rail for adjustment.

Installation Guide

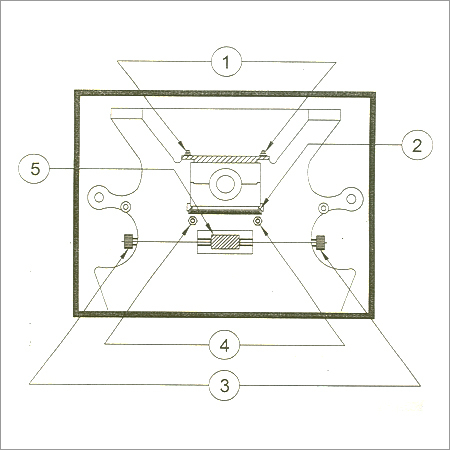

Install machine on foundation bolts. Check the machine level and tighten the foundation bolts. Apply grease / oil at required locations.

Start the machine and run it at no load condition for 2 hours. Thereafter, run the machine with roller shaft for another 6 hours. For first 3 days. run the machine 8 hours a day and after 3 days, machine can be operated up to 22 hours a day. There should be break a of 30 minutes after every 5 hours.

Size of the leather washer for roller shaft should be 7-1/4" dia. duly well pressed and turned by using centres on both the sides.

- Distance between two grooves in chrome leather roller should not be more then

- The depth of the groove should be mm

- In case feather roller becomes smooth, apply rough file on the rollers.

- Before feeding the cotton, groove the rolls.

While running the machine, check all the bearings and moving parts. If you found heated up, shut-off the machine. Apply grease at greasing points and again start the machine. Also check alignment and fittings of the parts. All the nuts and bolts are to be properly tightened.

Operating speed should not exceed 1000 RPM, otherwise parts are likely to break or damage and also quality of the lint and seed will not be proper.

Do not open beater bearing housing until you reqI,Jire.

The spaces between the fixed knives and moving knives should be equal on each side. In case of misalignment between the moving knife and the fixed knife, the same should be removed by inserting the packing between the beater arms and the moving knife.

Cut-off of the beater is governed by the length of the staple of the cotton to be ginned. Normally, it is more than 1/3 of the staple length. By increasing the cut-off, thinner lint is received and by reducing the cut-off thicker lint is received. The edges of the fixed knives are to be set to 86 'mm from the bottom of the knife rail by using gauge.

The edges of the moving knives should clear the upper edges of the fixed knives by about 1/16" along the entire length of fixed knives on both the sides. This is regulated by inserting or by removing the beater assembly by packing plates.

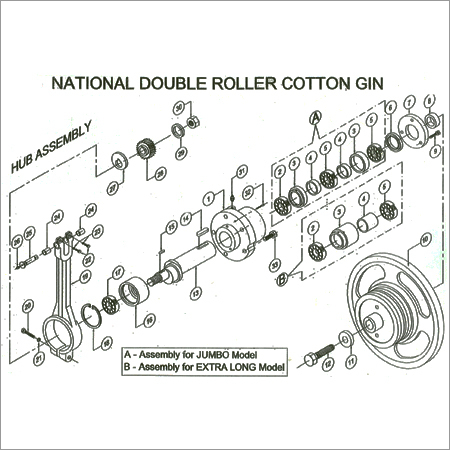

Set the fixed knives using gauge. Then set the beater level from the edges of the fixed knives. i.e. set the moving knives parallel to the fixed knives, this is affected by inserting or by removing the packing plates. The,oscillating head must be placed, on the beater shaft, but not tightened. The oscillating lever and wrist pin must be inserted and connected to the connecting rod. The moving knives must be set in such a way that strokes on both the sides are equal, i.e. Overlap on both sides should be equal. For this purpose, adjustment is made by setting the oscillating head. Loosen the oscillating head from the beater on the side, where the overlap is less. This will correct the overlap. When the overlap is properly adjusted, tightened the oscillating head fully.

Lubrication Guide

Other Products in 'Cotton Ginning Machine Spare Parts' category

|